Ogwe Gburugburu Igwe anaghị agba nchara nwere ezigbo mma

Nhazi ihe owuwu

Ígwè (Fe): bụ ihe bụ isi nke ígwè anaghị agba nchara;

Chromium (Cr): bụ isi ihe na-akpụ ferrite, chromium jikọtara ya na oxygen nwere ike imepụta ihe nkiri passivation Cr2O3 nke na-eguzogide nchara, bụ otu n'ime ihe ndị bụ isi nke ígwè anaghị agba nchara iji nọgide na-eguzogide nchara, ọdịnaya chromium na-eme ka ikike ndozi ihe nkiri passivation nke ígwè dịkwuo elu, ọdịnaya chromium nke ígwè anaghị agba nchara zuru oke ga-adị n'elu 12%;

Carbon (C): bụ ihe siri ike nke na-akpụ austenite, nwere ike ime ka ike ígwè ka mma nke ukwuu, na mgbakwunye na carbon na-eguzogide nchara nwekwara mmetụta ọjọọ;

Nickel (Ni): bụ isi ihe na-akpụ austenite, nwere ike ibelata nchara ígwè na uto nke ọka n'oge a na-ekpo ọkụ;

Molybdenum (Mo): bụ ihe na-akpụ carbide, carbide e guzobere na-adịgide nke ukwuu, nwere ike igbochi uto ọka nke austenite mgbe a na-ekpo ọkụ, belata mmetụta okpomọkụ dị elu nke ígwè, na mgbakwunye, molybdenum nwere ike ime ka ihe nkiri passivation dịkwuo oke ma sie ike, si otú a na-eme ka iguzogide nchara ígwè anaghị agba nchara nke ọma.

Niobium, titanium (Nb, Ti): bụ ihe siri ike nke na-akpụ carbide, nwere ike ime ka ígwè ahụ ghara iguzogide nchara dị n'etiti granular. Agbanyeghị, titanium carbide nwere mmetụta ọjọọ na ịdị mma nke ígwè anaghị agba nchara, yabụ a na-ejikarị ígwè anaghị agba nchara nke nwere ihe dị elu achọ mma site na itinye niobium iji melite arụmọrụ.

Nitrogen (N): bụ ihe siri ike nke na-akpụ austenite, nwere ike ime ka ike ígwè ka mma nke ukwuu. Mana mgbawa nke ígwè anaghị agba nchara na-akawanye njọ, yabụ ígwè anaghị agba nchara na-eji stampụ eme ihe iji chịkwaa ọdịnaya nitrogen nke ọma.

Phosphorus, sọlfọ (P, S): bụ ihe na-emerụ ahụ n'ime ígwè anaghị agba nchara, iguzogide nchara na stampụ nke ígwè anaghị agba nchara nwere ike inwe mmetụta ọjọọ.

Ngosipụta Ngwaahịa

Elu na Arụmọrụ

| ihe | Àgwà |

| 310S igwe anaghị agba nchara | 310S igwe anaghị agba nchara bụ austenitic chromium-nickel igwe anaghị agba nchara nke nwere ezigbo iguzogide oxidation, iguzogide nchara, n'ihi pasentị dị elu nke chromium na nickel, 310S nwere ike ịrị elu ka mma, ọ nwere ike ịnọgide na-arụ ọrụ n'okpomọkụ dị elu, yana ezigbo iguzogide okpomọkụ dị elu. |

| Ogwe gburugburu igwe anaghị agba nchara 316L | 1) Ọdịdị mara mma nke ngwaahịa oyi kpọchiri akpọchi mara mma ma na-egbuke egbuke. 2) ezigbo iguzogide nchara, ọkachasị iguzogide olulu mmiri, n'ihi mgbakwunye nke Mo 3) ike okpomọkụ dị elu nke ọma; 4) ike siri ike nke ọma (njirimara magnetik adịghị ike mgbe nhazi gasịrị) 5) enweghị magnetik n'ọnọdụ ngwọta siri ike. |

| 316 ígwè anaghị agba nchara ígwè ígwè gburugburu | Àgwà: 316 ígwè anaghị agba nchara bụ ígwè nke abụọ a na-ejikarị eme ihe mgbe 304 gasịrị, nke a na-ejikarị eme ihe n'ụlọ ọrụ nri na ngwa ịwa ahụ, n'ihi mgbakwunye nke Mo, yabụ iguzogide nchara ya, iguzogide nchara ikuku na ike okpomọkụ dị elu dị mma karịsịa, enwere ike iji ya n'ọnọdụ siri ike; ike ọrụ dị mma (anaghị ejikọta ya na magnet). |

| 321 ígwè anaghị agba nchara ígwè ígwè gbara gburugburu | Àgwà: Mgbakwunye nke ihe ndị dị na Ti na ígwè 304 iji gbochie ire ere ọka, nke dị mma maka ojiji na okpomọkụ nke 430 ℃ - 900 ℃. E wezụga itinye ihe ndị dị na titanium iji belata ihe ize ndụ nke ire ere ihe onwunwe, ihe ndị ọzọ yiri 304. |

| 304L igwe anaghị agba nchara ígwè gbara gburugburu | Ígwè gbara gburugburu nke 304L anaghị agba nchara bụ ụdị ígwè anaghị agba nchara 304 nwere obere ọdịnaya carbon ma a na-eji ya eme ihe n'ebe achọrọ ịgbado ọkụ. Ọdịnaya carbon dị ala na-ebelata mmiri ozuzo nke carbide na mpaghara okpomọkụ metụtara nso na weld, nke nwere ike ibute nchara dị n'etiti granular (mgbaze weld) nke ígwè anaghị agba nchara n'ebe ụfọdụ. |

| 304 ígwè anaghị agba nchara ígwè gburugburu | Àgwà: 304 ígwè anaghị agba nchara bụ otu n'ime ígwè anaghị agba nchara chromium-nickel a na-ejikarị eme ihe, nwere ezigbo iguzogide nchara, iguzogide okpomọkụ, ike okpomọkụ dị ala na ihe onwunwe igwe. Nguzogide nchara n'ikuku, ọ bụrụ na ikuku ụlọ ọrụ mmepụta ihe ma ọ bụ ebe mmetọ dị arọ, ọ dị mkpa ka a hichaa ya n'oge iji zere mmebi nchara. |

Ojiji A Na-ejikarị

E ji ígwè gbara gburugburu nke anaghị agba nchara rụọ ọrụ nke ọma, a na-ejikwa ya eme ihe n'ọtụtụ ebe na ngwaike na ihe eji esi nri, ụgbọ mmiri, petrochemical, igwe, ọgwụ, nri, ike eletrik, ike, ikuku, wdg, owuwu na ịchọ mma. Ngwa eji eme ihe n'ime mmiri oké osimiri, kemịkalụ, agba, akwụkwọ, oxalic acid, fatịlaịza na ngwa mmepụta ndị ọzọ; foto, ụlọ ọrụ nri, ebe a na-emepụta ihe n'akụkụ osimiri, eriri, mkpara CD, bolt, mkpụrụ

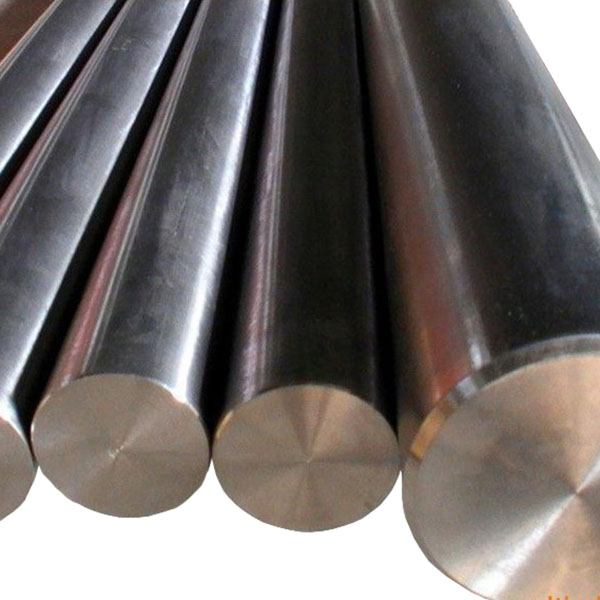

Ngwaahịa Ndị Bụ Isi

Enwere ike kewaa ogwe ígwè gbara gburugburu nke anaghị agba nchara n'ime nke a na-akpọ "hot rolled", nke a kpụrụ akpụ, nke a na-akpọ "forged", nke a na-akpọ "cool drawing" dịka usoro mmepụta si dị. Nkọwapụta ígwè gbara gburugburu nke ígwè anaghị agba nchara nke a na-akpọ "hot rolled" maka 5.5-250 mm. N'ime ha: 5.5-25 mm nke obere ígwè anaghị agba nchara nke a na-enyekarị n'ime ngwugwu ogwe kwụ ọtọ, nke a na-ejikarị eme ihe dị ka ogwe ígwè, bolts na akụkụ igwe dị iche iche; ígwè gbara gburugburu nke ígwè anaghị agba nchara nke karịrị 25 mm, nke a na-ejikarị eme ihe n'ịmepụta akụkụ igwe ma ọ bụ maka billet ígwè na-enweghị ntụpọ.