Igwe anaghị agba nchara

-

Mpekere waya ọla kọpa

Mpekere waya ọla kọpa bụ ihe na-eduzi igwe.Isi ihe bụ ọla kọpa.A na-ejikarị arụ ọrụ mmepụta ihe.

-

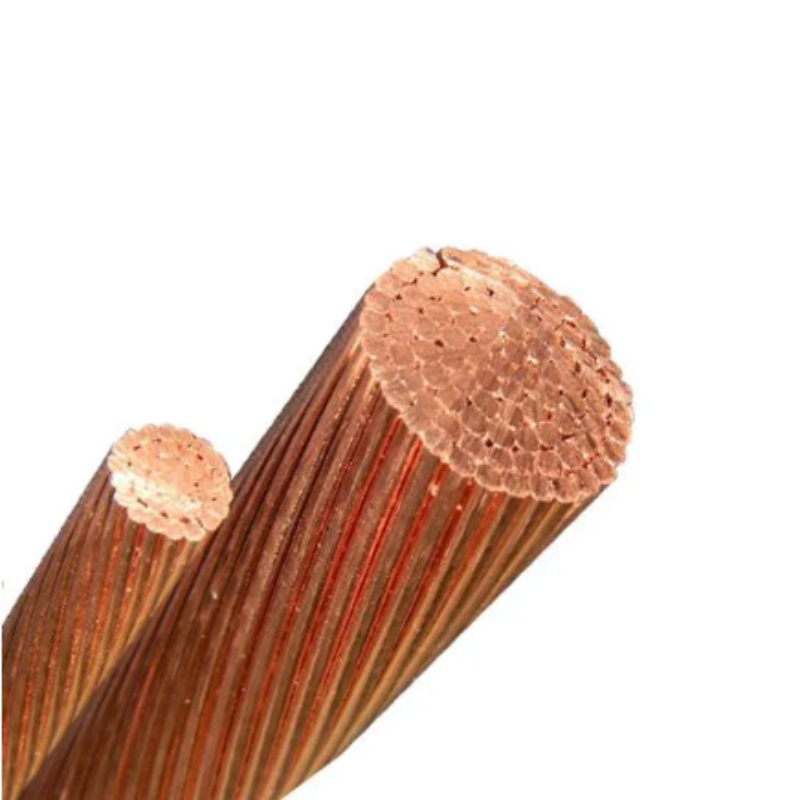

waya ọla kọpa

Waya ọla kọpa nwere ezigbo ọkụ eletrik na ọkụ ọkụ, nguzogide corrosion na ihe eji arụ ọrụ, enwere ike ịgbanye ya na brazed.Nwere mbelata eletriki na thermal conductivity adịghị, Chọpụta oxygen nwere obere mmetụta na eletriki na thermal conductivity na nhazi Njirimara, ma dị mfe na-akpata "hydrogen ọrịa", ekwesịghị ịbụ na elu okpomọkụ (dị ka> 370 ℃) na mbenata ikuku nhazi (dị ka> 370 ℃) annealing, ịgbado ọkụ, wdg) na ojiji.

-

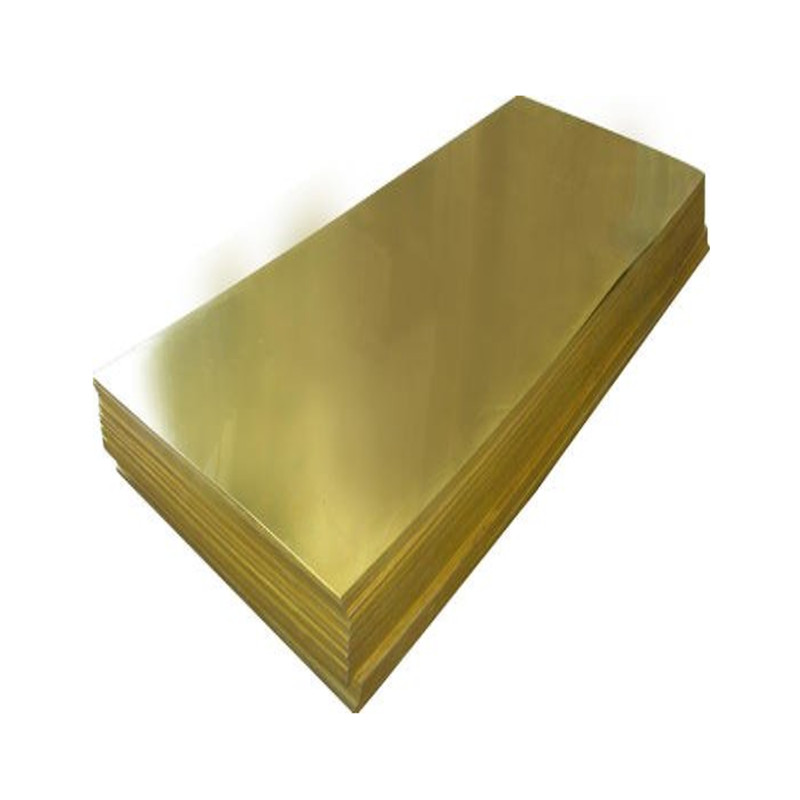

Efere ọla kọpa maka ụlọ ọrụ mmepụta ihe na ihe owuwu

Ezigbo ihe eji arụ ọrụ, ezigbo plasticity na steeti ọkụ, ezigbo plasticity na ọnọdụ oyi, ezigbo igwe, ịgbado ọkụ na ịgbado ọkụ dị mfe, nguzogide corrosion.

-

Brass ulo oru ọla kọpa dị ọcha efere ọla na tubes

Brass efere bụ ụdị nke ọtụtụ ebe-eji na-edu ndú brass, nwere ezi n'ibu Njirimara, na ezi machinability, nwere ike idi okpomọkụ na oyi na-atụ nhazi, eji na ọnwụ na stamping nhazi nke dị iche iche bughi akụkụ, dị ka gaskets, bushings, wdg Tin brass efere. nwere elu corrosion eguzogide, ezi n'ibu Njirimara, ezi nrụgide nhazi na oyi na-ekpo ọkụ na steeti, nwere ike iji maka corrosion eguzogide akụkụ na ụgbọ mmiri na uzuoku, mmanụ na ndị ọzọ media kọntaktị akụkụ na conduits.

-

Ọla kọpa dị ọcha mpempe akwụkwọ / efere / tube

Ọla kọpa nwere ezigbo ọkụ eletrik na thermal conductivity, ezigbo plasticity, mfe na-ekpo ọkụ na ịpị na oyi na-atụ nhazi nhazi, a ọnụ ọgụgụ buru ibu nke na-eji na mmepụta nke waya, cable, brush, electric spark corrosion nke ọla kọpa na ndị ọzọ pụrụ iche chọrọ nke ọma eletriki conductivity ngwaahịa.